Designers and Integrators of

Specialty Services PCS engineers possess expertise in many aspects of electrical, computer and software engineering. Our primary focus is to automate factories, testing laboratories, warehouses or any facility that requires automated processes. Our technologies involve numerous variations of hardware and software related to the following:

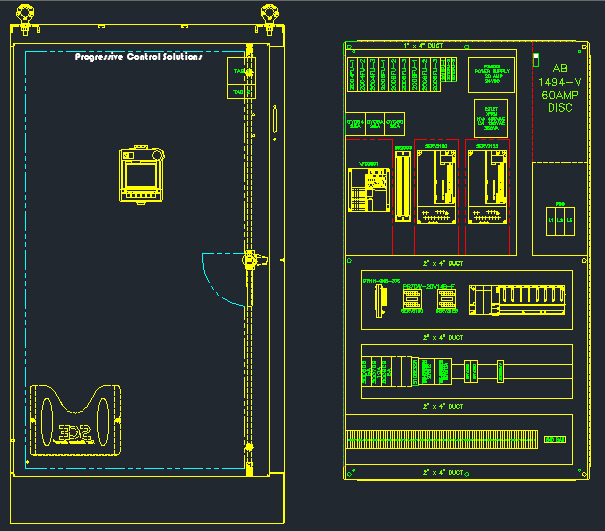

Controls Design

PCS can help improve your electrical schematics, enclosure design and component selection to make them more cost-effective.

De-Centralized/Centralized System Controls

Operator Interfaces

Data Collection Systems

Motor Control Centers

Low or High Voltage Controls

Embedded Systems

Knowledge of Typical Design and Safety Standards (NFPA, NEC, UL, OSHA, SCCR, etc.)

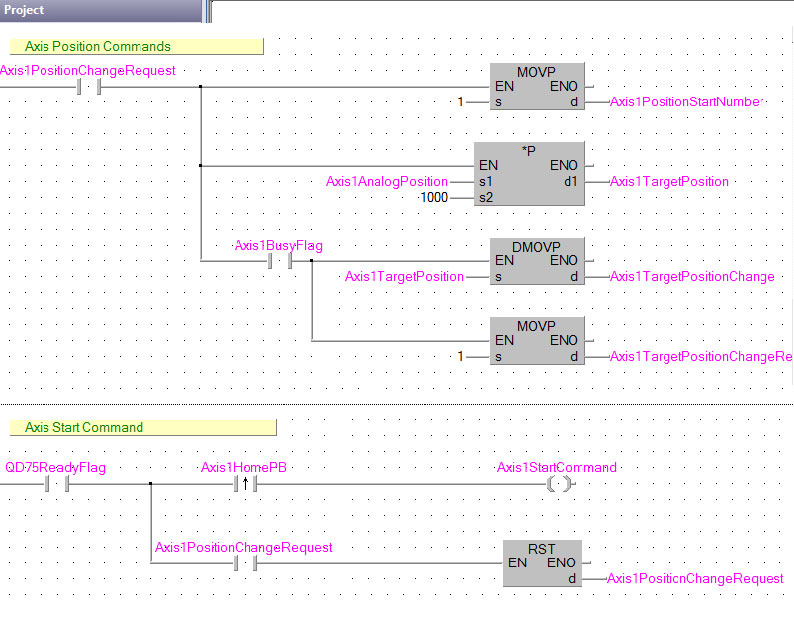

PLC Control

Ladder Logic, Structured Ladder, Structured Text, Function Blocks, Sequential Function Chart/Block.

PCS can help maximize your processes and increase production.

Material Handling

Motion Control

Robot Control

Process Control

High-Speed Control

Data Processing

Communications

Alarm Handling

Wireless Control

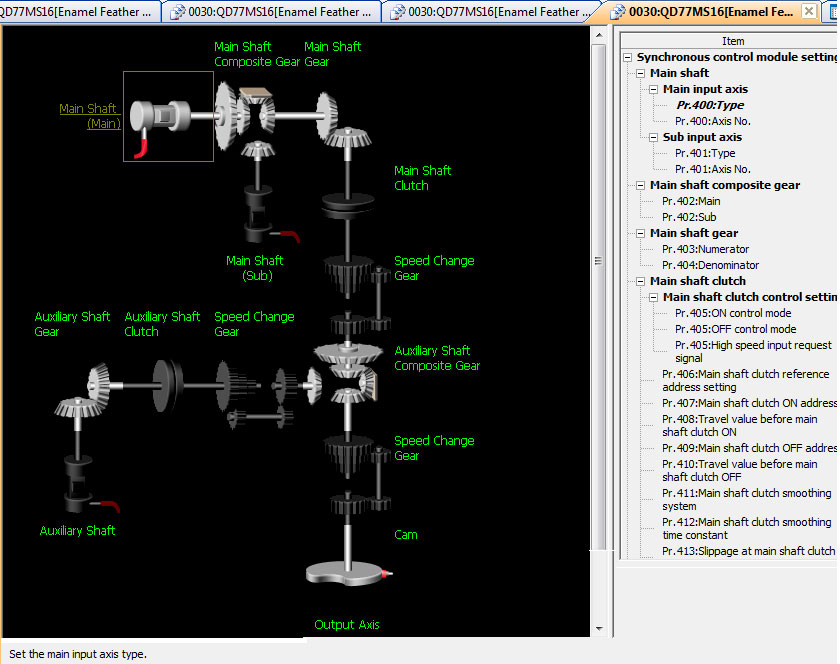

Servo/Motion Control

Induction Motors, Permanent Magnet Motors, Rotary Servo Motors, Linear Actuators.

PCS can help boost your system’s performance.

V/Hz Control

Sensorless Vector Control

Vector Control

Position Control

Point-to-Point Control

Velocity Control

Torque Control

Electronic Gearing/Camming

Multi-Axis Coordinated/Synchronized Motion

Process Control

Open-Loop, Closed-Loop, Discrete, Analog, Batch, Continuous.

PCS can help refine your process.

Temperature

Pressure

Flow

Level

Tension

Measurement

Coating

Mixing

Dispensing

LEL Monitoring

Waste Water Treatment

Energy Conservation

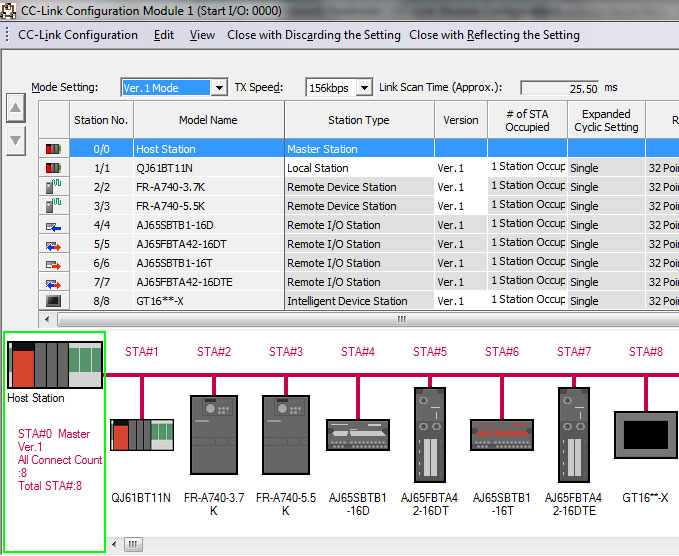

Networks

Enterprise Networks, Control Networks, Device Networks.

PCS can help design and commission the most efficient network for your application.

Ethernet/IP

Ethernet TCP/UDP

MelsecNet

CC-Link

ControlNet

FL-Net

Profinet

Profibus

Modbus

DeviceNet

ASI

Serial

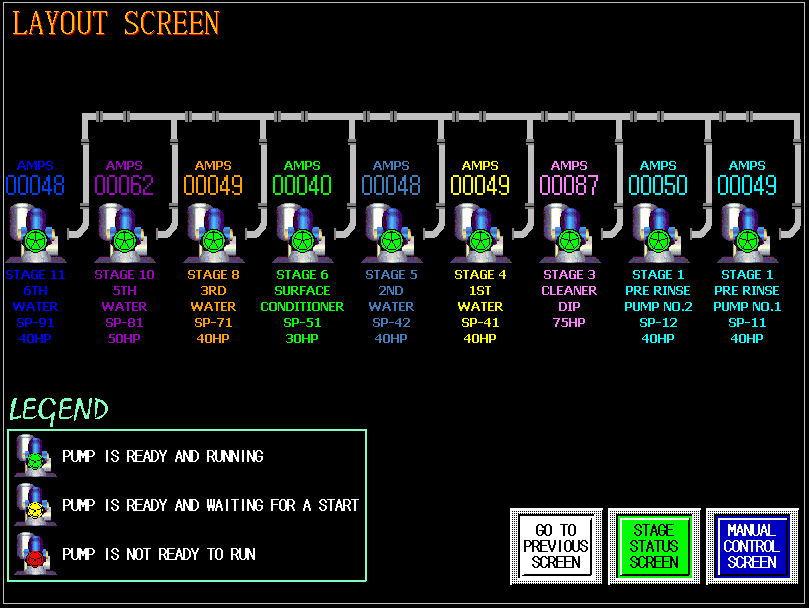

HMI/SCADA

Machine Status, Operator Interface, Production Dash Boards, Alarm Annunciation, Remote, Monitoring/Control.

PCS can help Simplify, Enhance and Visualize your processes or production.

Operator Stations

Touch Screen HMIs

LCD Text Displays

LED Marquee Displays

SCADA

MES/Data

Production Management, Enterprise Resource Planning, Advanced Planning and Scheduling, Supply Chain Management.

PCS can collect the data you need to help fine tune and efficiently manage your processes.

Overall Equipment Effectiveness

Key Performance Indicators

Process Management

Equipment Management

Quality Management

Cost Management

Inventory Management

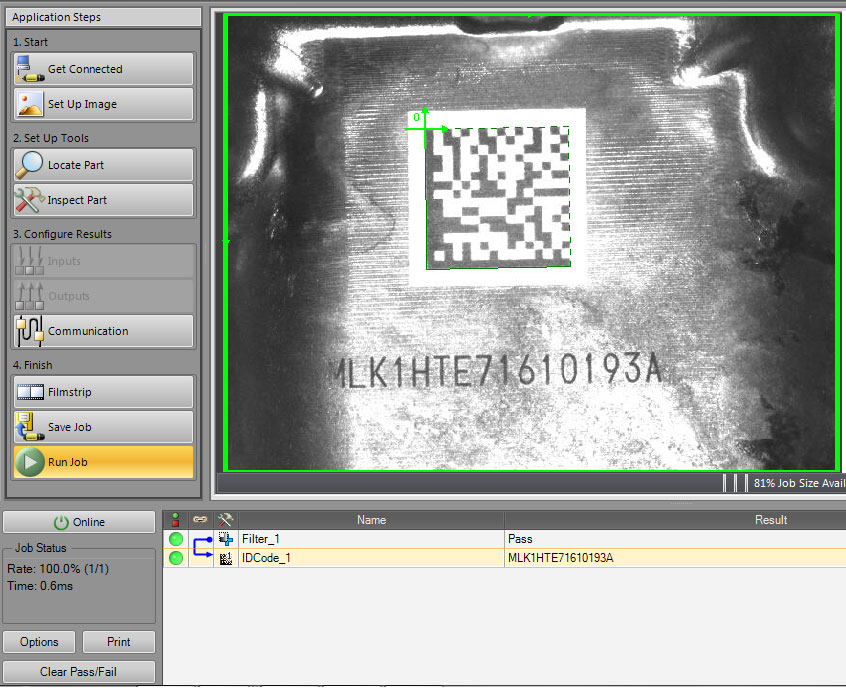

Identification/Traceability

Marking, Reading, Verifying, Tracking.

PCS can help optimize your product identification and traceability.

Laser Marking

Dot-Peen Marking

Bar Code Reading

Data Matrix Reading

RFID

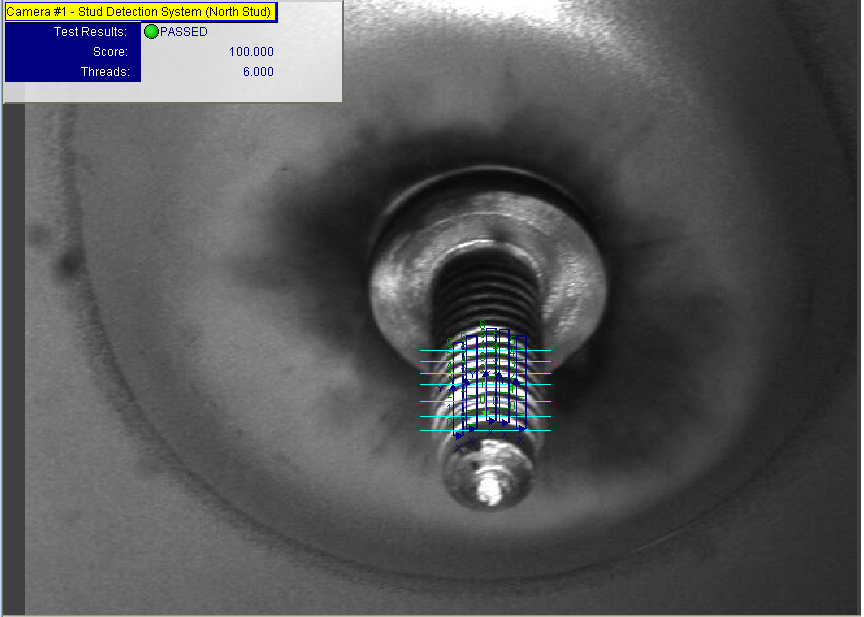

Error Proofing

Product Inspection, Assembly Verification, Sorting, Positioning, Tool Monitoring.

PCS can help perfect your manufacturing quality and efficiency.

Vision System

Object Detection Sensors

Measurement Sensors

Pick-To-Light Systems

Put-To-Light Systems

Contact Us for a